What Are You Looking For?

Rugged displays play a critical role in industries where standard consumer screens fail to survive. From factory floors and military vehicles to medical carts and outdoor kiosks, rugged displays are engineered to withstand harsh environments, extreme temperatures, vibration, dust, and moisture.

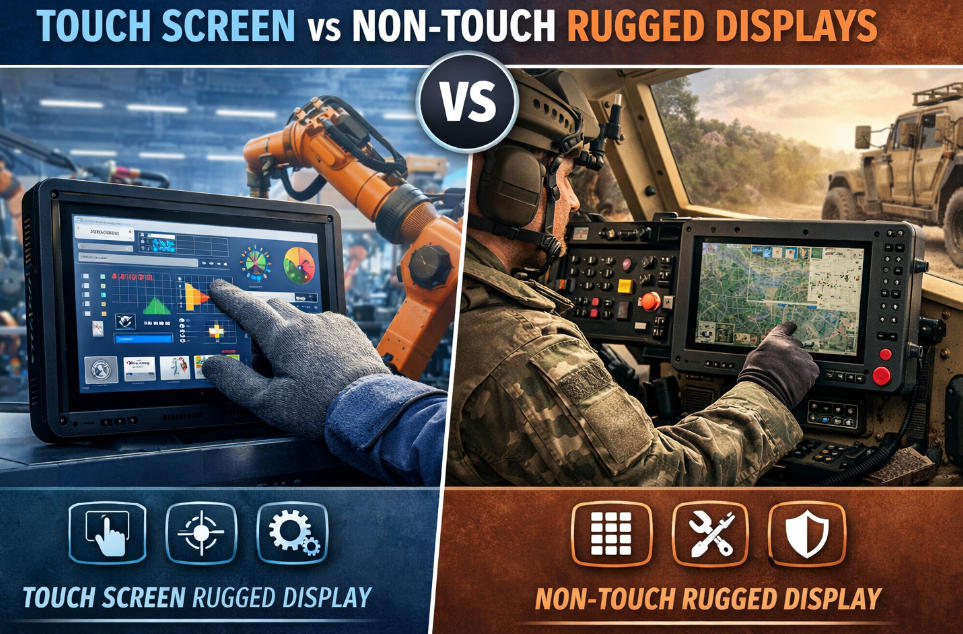

One of the most important decisions when selecting a rugged display is choosing between a touch screen rugged display and a non-touch rugged display. Each option offers distinct advantages depending on operational requirements, environmental conditions, and user interaction needs.

This article provides a detailed comparison of touch screen vs non-touch rugged displays, helping businesses identify which solution best fits their industry applications.

Rugged displays are industrial-grade monitors designed to operate reliably in demanding conditions. They typically feature:

Reinforced housings (metal or hardened polymer)

Wide operating temperature ranges

Shock and vibration resistance

High brightness and sunlight readability

Sealed designs with IP ratings for dust and water protection

Rugged displays are widely used in industries such as manufacturing, transportation, defense, healthcare, oil and gas, and public infrastructure.

A touch screen rugged display integrates a touch interface—such as resistive, capacitive, or infrared touch—into a ruggedized monitor. This allows users to interact directly with on-screen content using fingers, gloves, or styluses.

Resistive Touch: Works with gloves and styluses; ideal for industrial use

Projected Capacitive (PCAP): Supports multi-touch and high responsiveness

Infrared Touch: Suitable for large-format rugged displays

Intuitive and user-friendly interface

Reduces reliance on external input devices

Faster operation in space-constrained environments

Supports modern human-machine interface (HMI) designs

A non-touch rugged display functions purely as a visual output device and relies on external input methods such as keyboards, control panels, buttons, or joysticks.

Higher durability in extreme environments

Lower upfront cost

Reduced risk of accidental inputs

Easier maintenance and longer service life

Non-touch rugged displays are often preferred where interaction is limited or controlled through dedicated hardware.

Touch Screen Rugged Displays

Best suited for environments where operators need fast, direct interaction—such as factory automation, medical equipment, and logistics terminals. However, extreme cold, heavy rain, or muddy conditions may impact touch accuracy.

Non-Touch Rugged Displays

Perform better in ultra-harsh environments like military vehicles, mining sites, and offshore platforms where gloves, dirt, or vibration make touch input impractical.

Touch screen rugged displays are ideal when:

Operators need frequent interaction

Space is limited

Simplified training is required

Non-touch rugged displays are ideal when:

Interaction is minimal

Input is handled by physical controls

Precision is critical

While modern touch screens are highly durable, non-touch rugged displays typically have fewer failure points. In applications where uptime is mission-critical, a non-touch solution may offer greater long-term reliability.

Touch screen rugged displays generally have a higher initial cost due to integrated touch components and calibration requirements. Non-touch rugged displays are more cost-effective and may reduce total cost of ownership in long-term deployments.

Touch screens require regular cleaning and may be affected by scratches or surface wear. Non-touch rugged displays are easier to maintain and better suited for dusty or oily environments.

Recommended: Touch Screen Rugged Displays

Touch interfaces improve efficiency in HMI systems, PLC control, and production monitoring.

Recommended: Non-Touch Rugged Displays

Extreme conditions, vibration, and glove use make non-touch displays more reliable.

Recommended: Touch Screen Rugged Displays

Touch screens support quick data entry and hygienic interaction with sealed designs.

Recommended: Touch Screen Rugged Displays

Drivers benefit from intuitive navigation and system control, especially in compact cabins.

Recommended: Non-Touch Rugged Displays

Harsh environments with dust, moisture, and heavy equipment favor non-touch solutions.

Recommended: Touch Screen Rugged Displays

Public-facing systems require intuitive touch interaction with sunlight-readable displays.

When deciding between a touch screen and non-touch rugged display, consider the following questions:

How often will users interact with the display?

Will operators wear gloves or work in wet conditions?

Is space limited?

What level of durability is required?

What is the total cost of ownership over the product lifecycle?

A thorough evaluation of these factors ensures the rugged display aligns with operational needs and industry standards.

The decision between touch screen vs non-touch rugged displays is not about which technology is better overall, but which is better for your specific industry application. Touch screen rugged displays excel in environments that demand intuitive interaction and efficiency, while non-touch rugged displays offer unmatched durability and reliability in extreme conditions.

By understanding your industry requirements, environmental challenges, and user workflows, you can confidently select a rugged display solution that enhances productivity, safety, and long-term performance.